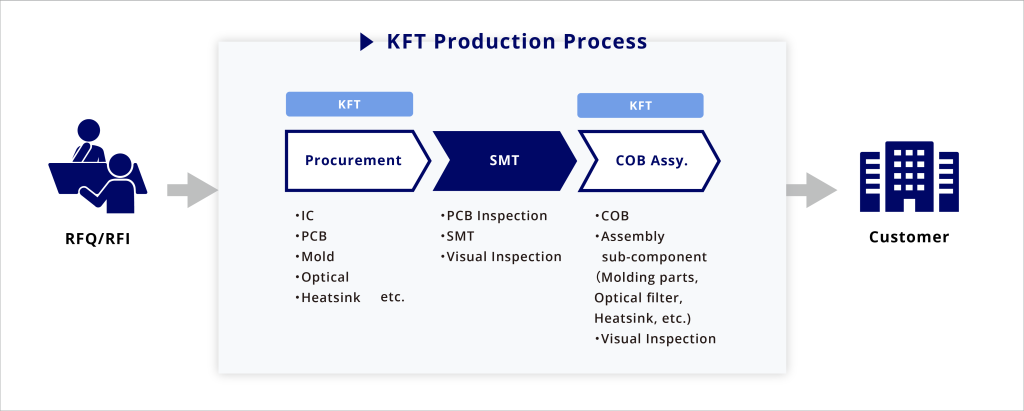

Image Sensor Module assembly COB(Chip on Board) Package Production Contract Manufacturing Service

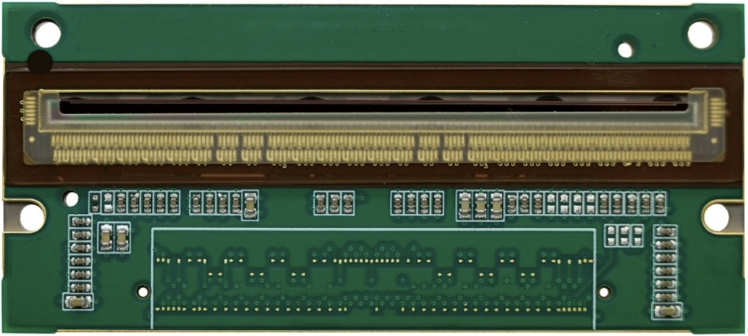

We can produce COB-package which directly die-bond (DB) and wire-bond (WB) Image sensor chip onto PCBA. One Stop service” is available from procurement of raw materials such as PCB, IC and other related materials to final assembly of COB-package.

Problems

R&D of soft X-ray/EUV conducted in a vacuum environment

- No suitable camera that is easy to use and install

- Limited space for installation

- Lacking in support for use (measures for outgassing, etc.).

Solutions

- Only the sensor-head can be installed into a vacuum environment by separating the sensor-head from the camera body, and it makes easier to set up the camera.

- R&D of Soft X-ray/EUV is facilitated by using a sensor sensitive to UV-area.

Background to Introduction

COB production of Image sensors is possible. COB package requires a lot of sub-components such as IC, PCB, Heatsink compared to normal package types, which increases supplier management cost. Our One Stop solution helps you to reduce management cost and to improve production efficiency.

We can provide One Stop service from procurement of raw materials to final assembly of COB-package. With Using our global network of Kanematsu Group and our Image sensor production know-how over 30 years, we can offer you high quality and flexible contract manufacturing services.

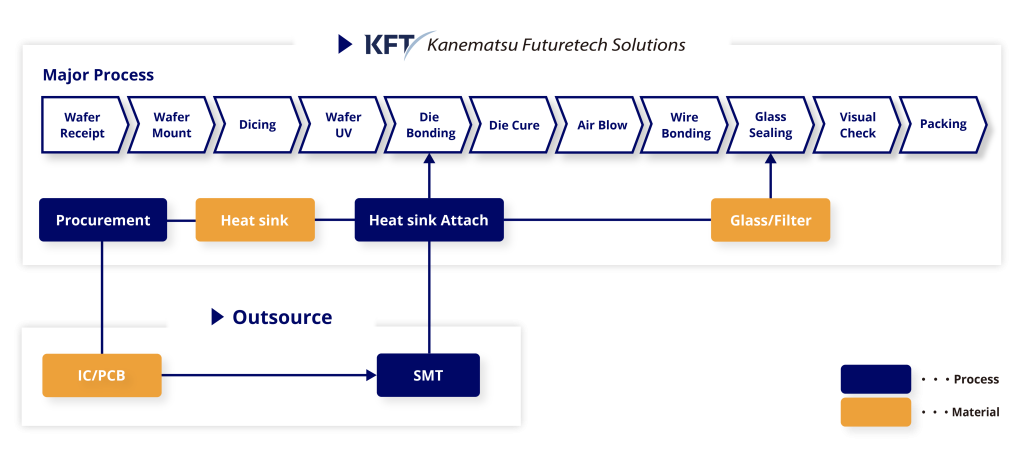

Major Process for COB package

We can provide “One Stop service” from material procurement to finished Image sensor module, as COB-package requires sub-component items compared to Normal Ceramic package process.

Message

Any requirements for special products and/or small volume are all welcomed.

With our global network of Kanematsu Group and our Image sensor production know-how over 30 years, we can offer you high quality and flexible manufacturing services.