SHT Corporation

SHT is the market leader in Japan for current sensor cores used in EVs and other vehicles. With an automated production system that can produce everything from cores to monolithic moldings and casings, SHT can offer a broad range of innovative proposals.

| Head office | Japan |

|---|---|

| Established | 1989 |

| Products | Sensor Cores, Current Transformer, Reactor, Choke Coil, GMK Transformer |

| URL | https://sht.co.jp/en/ |

Features

Magnetic properties guaranteed during mass production

・Coercive force standardized, magnetic properties after annealing guaranteed for the lot

・Coercive force inspection also performed at shipping inspection

Magnetic and electrical characteristics support

・SHT supports all required test measurements (0 – 1600 A) with our magnetic and electrical characteristics measurement environment.

Magnetic properties: Residual flux densty(Br), saturation (B-H characteristic), linearity

Electrical properties: Withstand voltage test of fully moldings

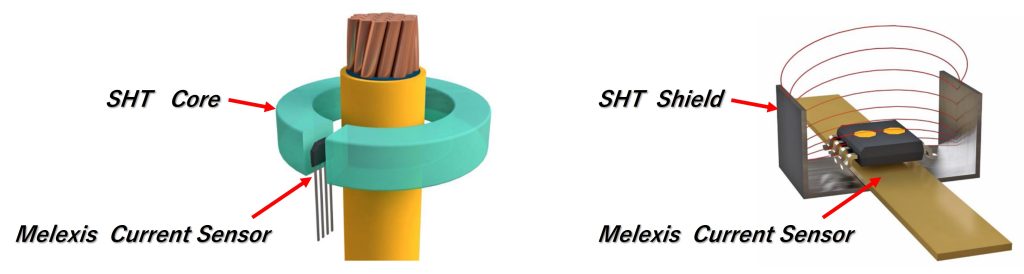

To get the most out of magnetic current sensor, it’s important to select the optimal product while taking into consideration the performance of the core and shield.

By proposing our Melexis current sensors together with SHT cores and shields, we can eliminate the need for component research, reduce the risk of mismatching the current sensor with the core or shield, and provide the optimal solution for your application.

*For current sensors, please refer to our website for the manufacturer “Melexis“.

Sensor Cores

Wound core

・Wound by our proprietary automatic winders for shapes with no line overlap

・Optimized temperature profile ensures excellent magnetic properties

Laminated core

・Non-oriented high-grade material is used to achieve the desired characteristics and cost performance

・Optimized temperature profile ensures excellent magnetic properties

Partially molded core

・Partial molding eliminates metal burrs

・Dimensional precision ideal for casing and molding

Fully molded core

・High quality and low cost achieved by automated production from core to fully molding

・Zero defects in products marketed

Casing core

・Ultrasonic welding eliminates degradation (of 20% or more) due to molding stress while achieving fundamental core properties

・High quality and low cost achieved by automated production from core to case

For more information

Contact Us